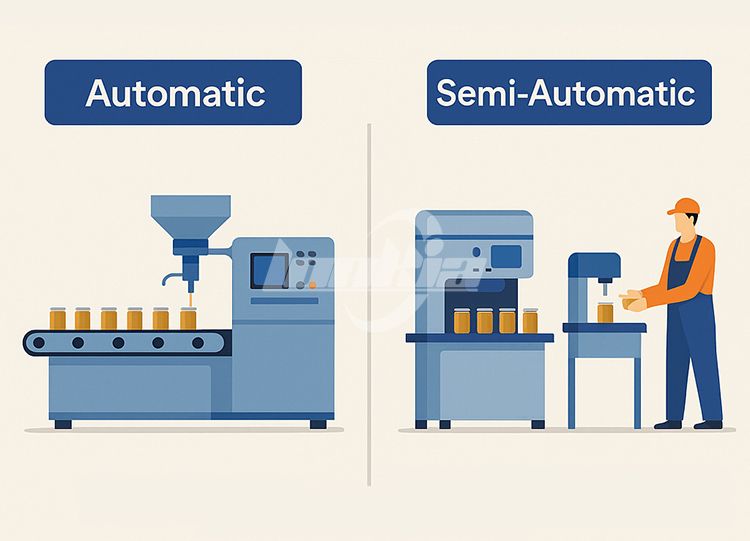

In the world of food manufacturing, choosing the right canning production line can significantly impact your operation’s efficiency, cost, and product consistency. Among the options available, automatic and semi-automatic canning production lines are the most common. But which one is better for your business? Let’s explore the key differences, advantages, and considerations.

1. What Is an Automatic Canning Production Line?

An automatic canning production line is a fully integrated system that performs all steps of the canning process with minimal human intervention. This includes:

Can depalletizing

Filling

Seaming/sealing

Sterilization or pasteurization

Labeling and packaging

These machines are ideal for high-volume food processing plants that need fast throughput and consistent quality.

Benefits:

High-speed operation

Reduced labor costs

Minimal human error

Consistent sealing and filling accuracy

Suitable for long-term scalability

2. What Is a Semi-Automatic Canning Production Line?

A semi-automatic line combines automation with manual tasks. Typically, operators are required to load cans or manually start some stages like filling or sealing.

This setup is common for small to medium-sized food processors, startups, or those with customized or variable products.

Benefits:

Lower initial investment

Easier to modify for different product types

Greater operator control for small-batch processing

Less complex maintenance and training

3. Key Factors to Consider When Choosing

| Factor | Automatic Line | Semi-Automatic Line |

| Production Volume | Best for high-volume | Best for low to medium volume |

| Labor Availability | Low operator requirement | Needs active human operation |

| Budget | High upfront investment | Lower cost to start |

| Flexibility | Fixed process, less flexible | More adaptable to product changes |

| Space Requirement | Larger footprint | Smaller footprint |

4. Which One is Right for You?

Here are some quick scenarios:

Choose automatic if you run a large food factory producing thousands of units daily, have the capital for investment, and prioritize long-term ROI.

Choose semi-automatic if you're scaling up from manual methods, want to control costs, or produce niche products with varying can sizes.

5. Final Thoughts

Choosing between automatic and semi-automatic canning production lines depends on your specific business needs, production goals, and budget. For consistent, large-scale output, an automatic line is often the better long-term solution. For flexibility and cost control, semi-automatic systems offer a great balance.

If you're unsure, consult with a professional canning equipment provider like LONKIA Machinery—we specialize in helping food processors build the right solution for their production needs.