Our Sardine Canning Production Line is specifically engineered to transform premium fresh sardines into high-quality, shelf-stable canned products. Designed to preserve the delicate flavor and texture of sardines, our production line integrates advanced cleaning, evisceration, and deboning technologies with precision filling, sealing, and high-pressure sterilization. The result is a consistent, nutritious product that meets stringent food safety standards and delivers superior taste.

Key Features

- High Capacity Processing

Throughput: 1-5 tons/hour

Modular & Scalable

- Precision Evisceration & Deboning

Efficiently removes heads, viscera, and bones

Ensures only premium meat is used

- Aseptic Filling & Sealing

Up to 120 cans/minute

Maintains filling precision within ±2%

- PRigorous Sterilization

Precise Temperature Control: Maintains 121°C ±0.5°C

Uniform Sterilization: Complete microbial safety

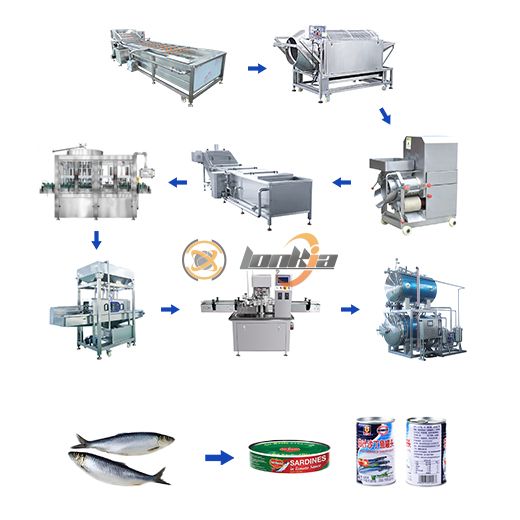

Key Machines of Sardine Canning Production Line

-

Washing Machine

This unit thoroughly cleans the fresh sardines, removing impurities, scales, and surface contaminants using high-pressure water jets and automated brush systems.

-

Drum Fish Scaling Machine

Designed specifically for sardines, this machine employs a rotating drum with soft, yet effective, scaling blades to gently remove scales without damaging the delicate skin.

-

Sardine Processing Segment

This segment integrates automated evisceration and initial trimming, where sardines are further processed to remove heads, viscera, and bones. Skilled operators supervise the process to ensure only premium meat proceeds.

-

Pre-Cooking Machine

The pre-cooking unit uses water-cooking techniques to partially cook the processed sardines. This step softens the meat, enhances flavor, and reduces microbial load before final packaging.

-

Automatic Filling Machine

This high-speed filling system accurately transfers pre-cooked sardine meat into sanitized cans, ensuring uniform volume and minimal waste across high production volumes.

-

Soup Filling Machine

Specially designed for adding pickling liquids or sauces, this machine precisely dispenses a controlled amount of brine into each can alongside the sardine meat, enhancing flavor and ensuring proper preservation.

-

Sealing Machine

Utilizing advanced heat-sealing or mechanical capping technology, this machine ensures each can receives an airtight, robust seal, protecting the product from contamination and oxidation.

-

High-Pressure Sterilization Retort

A critical unit that subjects the sealed cans to controlled high-temperature and high-pressure conditions, ensuring complete microbial inactivation while preserving the sardines’ flavor and nutritional profile.

-

Carton Packing System

Following sterilization, this automated system efficiently organizes and packs the cans into cartons, readying the product for storage and distribution.

-

Palletizing Machine

The final stage involves automated palletizing, where cartons are systematically stacked on pallets for secure transportation and storage.

Product Gallery

Technical Specifications

Capacity | Packaging |

1T/H | 5T/H | 10T/H | Tin Can | Glass Jar | Pouch |

Note: Technical specifications may change without notice due to ongoing technological advancements.

Applications

Canned Sardines

Canned Sardines

Canned Sardines

Canned Sardines

Ready to Transform Your Sardine Canning Process?

Our fully integrated sardine canning production line is engineered to maximize efficiency, preserve premium quality, and ensure robust food safety. Contact us today for a customized solution and detailed quote tailored to your production needs.

Request a Quote