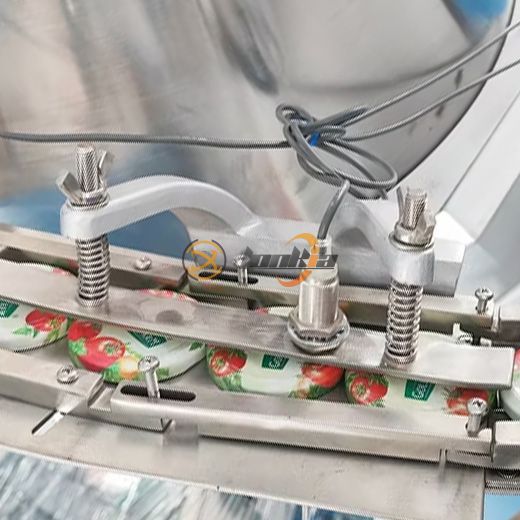

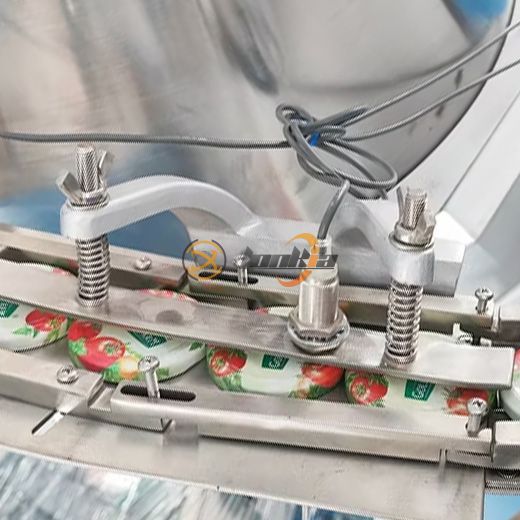

Our Vacuum Capping Machine is a cutting-edge sealing solution engineered to achieve a consistent, airtight closure on a variety of containers. Designed with advanced servo technology and precision controls, it efficiently evacuates air and secures lids, ensuring product freshness, extended shelf life, and uncompromised safety. Ideal for high-volume production in the food, beverage, this machine delivers reliable performance and superior sealing quality.

Key Features

- Precision SealingEmploys state-of-the-art servo technology to deliver a uniform, airtight seal on every container, effectively preventing oxidation and contamination.

- High ThroughputCapable of processing up to 2,200 bottles per hour, the machine is optimized for large-scale operations while maintaining stringent quality standards.

- Versatile Cap CompatibilityDesigned to handle various cap types, including tinplate and threaded caps, and adjustable to suit container diameters from 30–60 mm, making it adaptable to a wide range of packaging formats.

- User-Friendly OperationFeatures an intuitive touchscreen interface and programmable controls that simplify setup and reduce the need for extensive operator training.

Product Gallery

Applications

1罐头

2罐头

3罐头

4罐头

Technical Specifications

Specification | Details |

Power | 2KW |

Voltage | 380V; 50Hz; 3-phase |

Dimensions (L×W×H) | 3000×1200×1680 mm |

Material | 304 stainless steel |

Output Capacity | 1,800–2,200 bottles per hour |

Applicable Cap Diameter | 30–60 mm (suitable for a single cap type) |

Conveyor Belt Height | 750 ± 50 mm |

Note: Technical specifications may change without notice due to ongoing technological advancements.