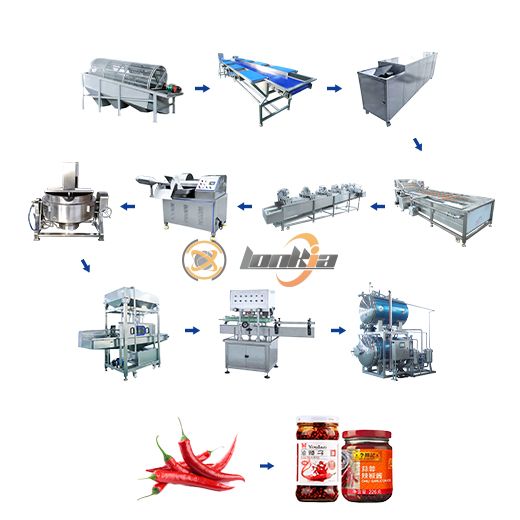

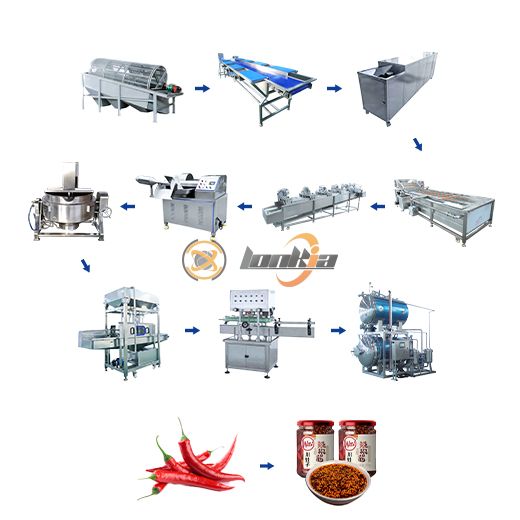

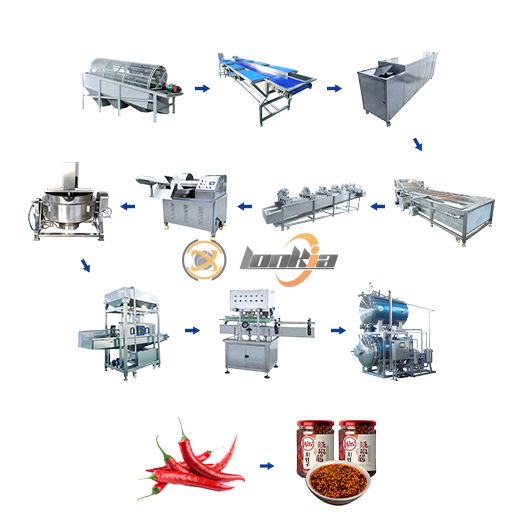

Our Canned Chili Sauce Processing Line is expertly engineered to convert fresh or pre-prepared chili into premium canned products. Utilizing advanced technology and automation, our production line carefully manages every step—from thorough cleaning and de-stemming to precise filling, vacuum sealing, and high-pressure sterilization. The result is a product that retains its robust flavor, vibrant color, and nutritional quality while achieving extended shelf life.

Key Features

- High Capacity Processing

Throughput: 1-5 tons/hour

Scalable Configuration Options

- Advanced Pre-Treatment Technology

Efficient Cleaning & De-Stemming

Product loss less than 3%.

- Aseptic Filling System

Filling Accuracy: ±2% ensures uniform fill levels

High-Speed Operation: 90-110 cans/minute

- Precision Sterilization

Maintains ±0.5°C temperature control accuracy

Effective Microbial Inactivation: F0 value ≥8

Key Machines of Canned Chili Sauce Processing Line

-

Bubble Washing Machine

Utilizes high-pressure micro-bubble jets to gently cleanse chili ingredients, efficiently removing soil, pesticides, and impurities without compromising product integrity.

-

Roller Brush Cleaning Machine

A soft rotating brush mechanically removes stubborn contaminants and residual stains in folds, ensuring a thorough and gentle cleaning process.

-

Pepper Stemming Machine

Designed specifically for peppers, this machine automatically removes the stems from the peppers, ensuring that the final product contains only the fruit.

-

Blanching Machine

Pre-cooks chili quickly to inactivate enzymes, lock in flavor, and prepare the product for further processing while preserving its vibrant color and texture.

-

Cooling Machine

Rapidly reduces the temperature of blanched chili to halt the cooking process, preserving its crisp texture and ensuring readiness for subsequent filling.

-

Automatic Chili Filling Machine

Precisely transfers pre-treated chili into containers, ensuring consistent portion control and minimizing waste.

-

Brine Filling Machine

Accurately dispenses pickling brine or chili sauce into containers, ensuring even distribution and proper product preservation.

-

Steam Vacuum Capping Machine

Employs a dual-action process of steam pre-heating and vacuum sealing to create an airtight closure on each container, preventing oxidation and extending shelf life.

-

High-Pressure Sterilization Retort

Exposes filled and sealed containers to controlled high-pressure heat, ensuring complete microbial inactivation while preserving the chili’s flavor and nutritional profile.

Product Gallery

Technical Specifications

Capacity | Packaging |

1T/H | 5T/H | 10T/H | Tin Can | Glass Jar | Pouch |

Note: Technical specifications may change without notice due to ongoing technological advancements.

Applications

Canned Chili Sauce

Canned Chili Sauce

Canned Chili Sauce

Canned Chili Sauce

Looking to Upgrade Your Chili Canning Line?

Our fully automated chili canning equipment is designed to maximize productivity, maintain robust product quality, and extend shelf life. Contact us today to explore customized solutions tailored to your production needs.

Request a Quote