Our Canned Cucumber Production Line is engineered to preserve the crisp texture and vibrant color of cucumbers while ensuring food safety and high throughput. Leveraging advanced automation and gentle handling technology, our line optimizes every stage—from raw material cleaning to vacuum sealing—to deliver shelf-stable cucumber products with consistent quality.

Key Features

- Gentle Cleaning System

Dual-stage washing

Damage rate<1%

- Precision Blanching

Temperature control: ±0.3℃

Time adjustment: 1-5 minutes

- High-Speed Filling

80-120 jars/minute

±1.5% filling accuracy

- Vacuum Sealing

99.9% airtight guarantee

Shelf life: up to 24 months

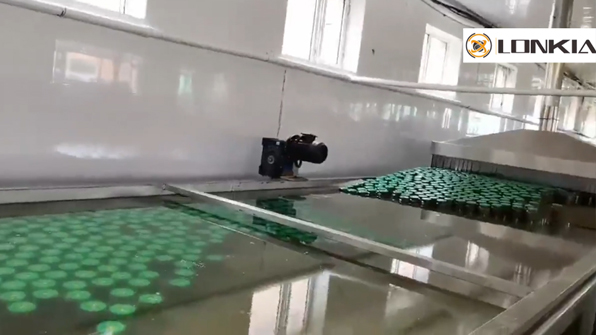

Production line video