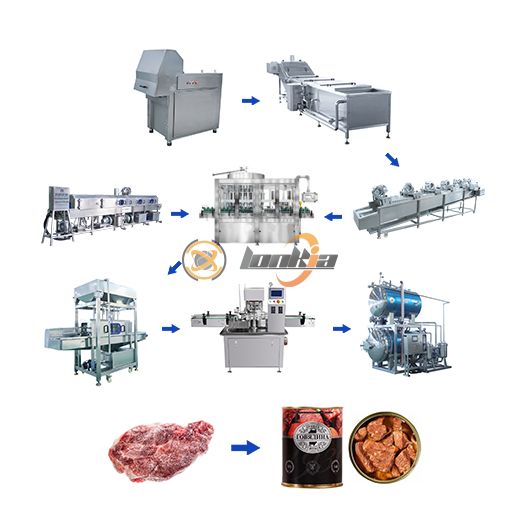

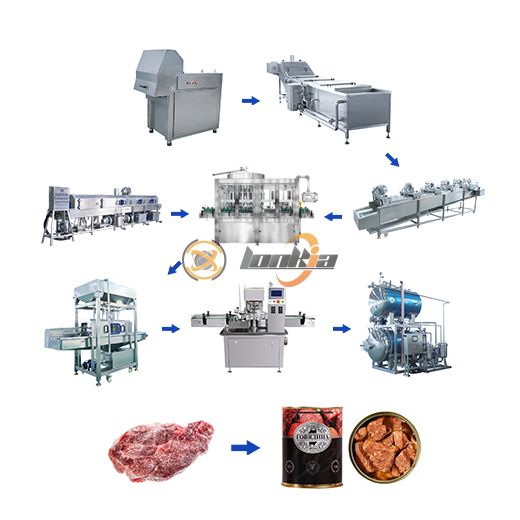

Our Canned Beef Production Line is engineered to transform frozen beef into high-quality, shelf-stable canned products. Designed for precision and efficiency, the production process is meticulously managed to preserve the natural flavor, tenderness, and nutritional value of the beef. Every step—from initial cutting of frozen meat to final sterilization—is optimized to deliver consistent, premium canned beef that meets strict food safety standards and satisfies even the most discerning palates.

Key Features

- High Capacity Processing

Throughput: 1-5 tons/hour

Modular design enables easy expansion

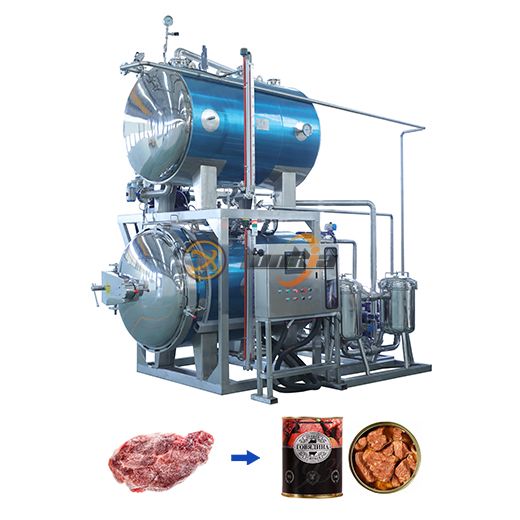

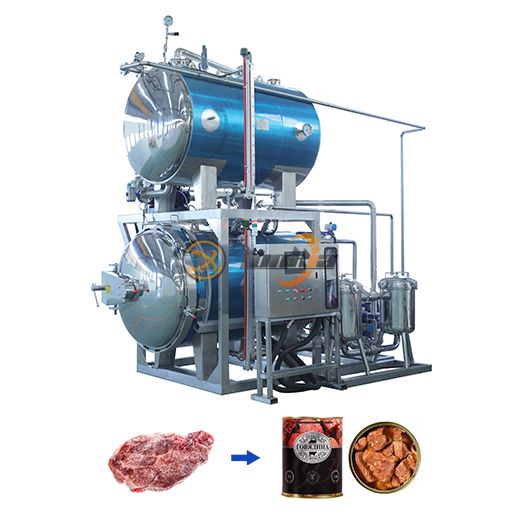

- Precision Thermal Processing

Controlled heating and rapid cooling maintain flavor

Thermal Accuracy: ±0.5°C

- Automated Filling & Seaming

Up to 110 cans per minute

Filling accuracy within ±2%

- Rigorous Sterilization

Operates at 121°C for 20-30 minutes

Ensures all containers are evenly sterilized

Production line video