Our Canned Luncheon Meat Production Line is specifically designed to transform high-quality meat and fat into a smooth, well-emulsified luncheon meat paste. With advanced processing technologies and robust automation, our production line meticulously controls every phase—from frozen meat cutting and fine grinding to emulsification, precise pre-cooking, rapid cooling, and high-speed filling. The result is a consistently flavorful, tender, and shelf-stable product that meets rigorous food safety standards.

Key Features

- Throughput: 1-5 tons/hour

Throughput: 1-5 tons/hour

Scalable Design

- Advanced Emulsification & Pre-Cooking

Achieves 98% homogeneity for consistent texture

±0.5°C accuracy during pre-cooking

- Automated Filling & Seaming

Up to 120 cans/minute

±2% filling precision for uniform portions

- Rigorous Sterilization

121°C for 20-30 minutes

Uniform Heat Distribution

Key Machines of Canned Luncheon Meat Production Line

-

Frozen Meat Cutting Machine

Designed specifically for handling frozen meat blocks, this machine precisely slices the frozen meat into uniform portions while minimizing thawing. Its advanced cutting mechanism ensures that the integrity, texture, and nutritional properties of the meat are preserved throughout the process.

-

Meat Grinder

The meat grinder employs multi-stage grinding technology to transform the cut frozen meat into a fine, homogenous meat paste. This process is crucial for achieving the ideal texture and consistency required for high-quality luncheon meat.

-

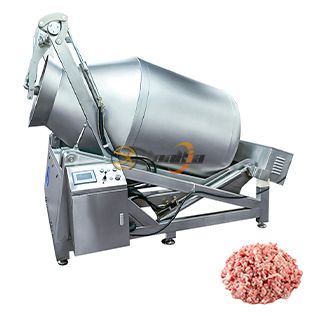

Vacuum Tumbling Machine

In a controlled vacuum environment, the vacuum tumbling machine performs gentle rolling and tumbling of the meat paste. This step aids in marinating and tenderizing the meat while ensuring that any excess air is removed, enhancing the overall stability and uniformity of the product.

-

Chopping & Mixing Machine

Combining the functions of chopping and mixing, this machine rapidly breaks down the meat paste along with any additional ingredients, resulting in a smooth, uniform blend. This process is essential for creating a consistent and finely emulsified product.

-

Vacuum Stirrer

The vacuum stirrer is engineered to mix the meat emulsion under vacuum conditions, preventing air incorporation and maintaining a stable emulsion. This machine enhances the overall homogeneity and creaminess of the luncheon meat while extending its shelf life.

-

6.Can Washing Machine

The Can Washing Machine is a critical component designed to thoroughly clean and sanitize empty cans prior to filling. This machine employs a multi-stage cleaning process that uses heated water, detergents, and high-pressure jets to remove any residues, ensuring a contaminant-free container environment.

-

Filling Machine

This high-precision filling machine accurately dispenses the prepared meat paste into cans or jars, ensuring consistent volume and minimal product waste. Its advanced metering system guarantees that each container is filled to the exact specification required for quality assurance.

-

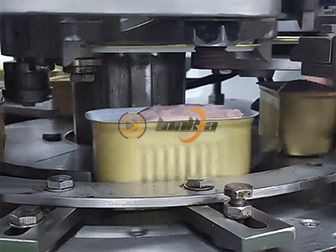

Can Sealing Machine

The Can Sealing Machine employs advanced mechanical capping technology to secure an airtight closure on each can. This critical step ensures that the canned product remains protected from contamination, oxidation, and spoilage, thereby preserving flavor and extending shelf life.

-

Sterilization Retort Machine

The final stage in the production line, the sterilization retort subjects the sealed containers to controlled high-pressure and high-temperature conditions, effectively eliminating all microbial hazards. This process ensures that the luncheon meat is safe for consumption and can be stored for extended periods.

Product Gallery

Technical Specifications

Capacity | Packaging |

1T/H | 5T/H | 10T/H | Tin Can | Glass Jar | Pouch |

Note: Technical specifications may change without notice due to ongoing technological advancements.

Applications

Canned Luncheon Meat

Canned Luncheon Meat

Canned Luncheon Meat

Canned Luncheon Meat

Ready to Elevate Your Luncheon Meat Canning Process?

Our state-of-the-art luncheon meat canning line is engineered to maximize productivity, enhance flavor, and ensure rigorous food safety standards. Contact us today to receive a customized solution and a detailed quote tailored to your production needs.

Request a Quote