Why Invest in a Fully Automatic Canning Production Line?

In the fast-paced world of food manufacturing, efficiency, consistency, and hygiene are non-negotiable. For companies aiming to scale up their production while ensuring top-tier product quality, a fully automatic canning production line is a game-changer. Here's why making this investment can significantly elevate your operation.1. Maximized Production EfficiencyFully automatic canning lines streamline the entire process — from filling and sealing to sterilizing and labeling — with minimal human intervention. These systems can operate continuously and at high speeds, dramatically increasing your daily…

Learn MoreExploring the Benefits of Vacuum Canning in Modern Production Lines

In today’s competitive food manufacturing landscape, ensuring product freshness, shelf stability, and food safety is paramount. One technology that has proven essential in achieving these goals is vacuum canning. By removing air from the can before sealing, vacuum canning significantly enhances product quality and extends shelf life — making it a preferred choice in modern canning production lines.What Is Vacuum Canning?Vacuum canning is a process where air is removed from a can or jar before it is sealed. This vacuum environment prevents oxidation, inhibits the growth of bacteria and molds, and…

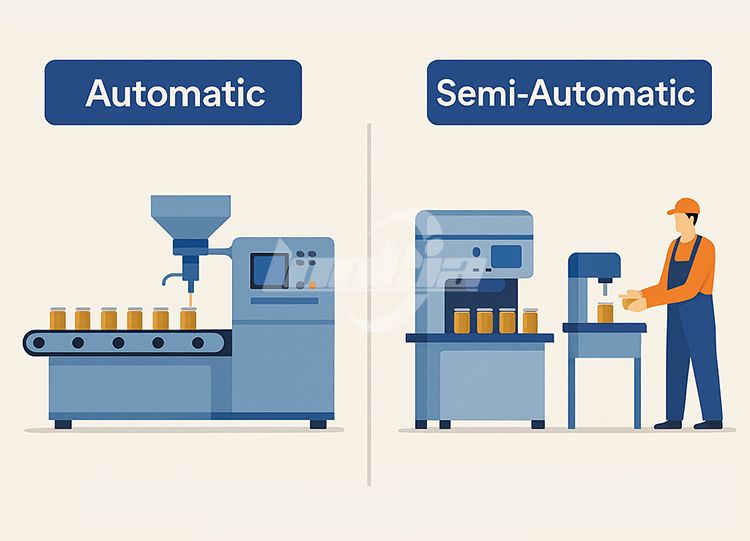

Learn MoreAutomatic vs. Semi-Automatic Canning Production Lines: Which One is Right for You?

In the world of food manufacturing, choosing the right canning production line can significantly impact your operation’s efficiency, cost, and product consistency. Among the options available, automatic and semi-automatic canning production lines are the most common. But which one is better for your business? Let’s explore the key differences, advantages, and considerations.1. What Is an Automatic Canning Production Line?An automatic canning production line is a fully integrated system that performs all steps of the canning process with minimal human intervention. This includes:Can depalletizingFillingSea…

Learn MoreWhat Is a Canning Production Line and How Does It Work?

In today’s fast-paced food industry, efficiency, hygiene, and shelf life are critical. One of the most effective ways to preserve food products—whether fruits, vegetables, meats, or ready-to-eat meals—is through canning. But how do manufacturers achieve this on a massive scale? The answer lies in a canning production line.In this article, we’ll explore what a canning production line is, the key components involved, and how the entire process works to safely preserve food while maintaining quality and flavor.What Is a Canning Production Line?A canning production line is a fully integrated system of…

Learn More

Our Peach Canning Production Line is engineered for precision and efficiency, specifically designed to maximize yield while preserving the natural flavor, texture, and nutritional value of peaches. With cutting-edge technology and specialized equipment, our system seamlessly integrates every stage—from initial cleaning and peeling to pitting, slicing, filling, and high-pressure sterilization—to deliver top-quality canned peaches with consistent taste, vibrant color, and extended shelf life.

Learn More

Our Canned Tomato Production Line is engineered for precision and efficiency, designed to maximize yield while preserving the quality and nutritional value of tomatoes. With cutting-edge technology, our equipment optimizes every stage of the canning process to deliver top-quality canned tomatoes with consistent taste, texture, and color.

Learn More

Our Canned Beef Production Line is engineered to transform frozen beef into high-quality, shelf-stable canned products. Designed for precision and efficiency, the production process is meticulously managed to preserve the natural flavor, tenderness, and nutritional value of the beef. Every step—from initial cutting of frozen meat to final sterilization—is optimized to deliver consistent, premium canned beef that meets strict food safety standards and satisfies even the most discerning palates.

Learn More

Our Canned Tuna Production Line is engineered to transform premium fresh or frozen tuna into high-quality, shelf-stable canned products. Designed for maximum yield and consistent product quality, our process carefully manages every stage—from thawing and cleaning to precise deboning, cooking, cooling, filling, seaming, and high-pressure sterilization. The result is a canned tuna product that retains its natural flavor, texture, and nutritional value while meeting the highest food safety standards.

Learn MoreCanned Luncheon Meat Production Line

Our Canned Luncheon Meat Production Line is specifically designed to transform high-quality meat and fat into a smooth, well-emulsified luncheon meat paste. With advanced processing technologies and robust automation, our production line meticulously controls every phase—from frozen meat cutting and fine grinding to emulsification, precise pre-cooking, rapid cooling, and high-speed filling. The result is a consistently flavorful, tender, and shelf-stable product that meets rigorous food safety standards.

Learn MoreSardine Canning Production Line

Our Sardine Canning Production Line is specifically engineered to transform premium fresh sardines into high-quality, shelf-stable canned products. Designed to preserve the delicate flavor and texture of sardines, our production line integrates advanced cleaning, evisceration, and deboning technologies with precision filling, sealing, and high-pressure sterilization. The result is a consistent, nutritious product that meets stringent food safety standards and delivers superior taste.

Learn MorePineapple Canning Production Line

Our Strawberry Canning Production Line can handle delicate strawberries with utmost care while preserving their vibrant color, natural flavor, and nutritional value. This fully integrated system streamlines every phase—from gentle washing and destemming to aseptic filling, secure sealing, and high-pressure sterilization—ensuring a consistently premium, shelf-stable canned product that meets rigorous food safety standards.

Learn MoreStrawberry Canning Production Line

Our Strawberry Canning Production Line is meticulously designed to handle delicate strawberries with utmost care while preserving their vibrant color, natural flavor, and nutritional value. This fully integrated system streamlines every phase—from gentle washing and destemming to aseptic filling, secure sealing, and high-pressure sterilization—ensuring a consistently premium, shelf-stable canned product that meets rigorous food safety standards.

Learn MoreCorn & Beans Canning Production Line

Our Corn & Beans Canning Production Line is meticulously designed to convert raw beans and corn into premium, shelf-stable canned products. Leveraging state-of-the-art automation and precision engineering, our production system optimizes every step—from thorough cleaning and grading to controlled pre-cooking, filling, and sterilization. This integrated approach ensures that every can delivers consistent texture, vibrant flavor, and exceptional nutritional quality.

Learn MoreCanned Chili Sauce Processing Line

Our Canned Chili Sauce Processing Line is expertly engineered to convert fresh or pre-prepared chili into premium canned products. Utilizing advanced technology and automation, our production line carefully manages every step—from thorough cleaning and de-stemming to precise filling, vacuum sealing, and high-pressure sterilization. The result is a product that retains its robust flavor, vibrant color, and nutritional quality while achieving extended shelf life.

Learn More